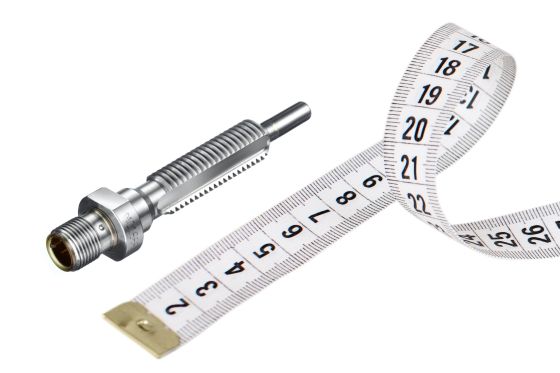

Temperature sensor with platinum measuring element PT100

Thanks to the platinum measuring element PT100 (according to DIN EN 60751, class A) used, the media temperature can be detected much faster and more precisely than is possible with conventional bi-metal temperature switches.

The temperature sensors made of stainless steel 1.4305 of type TS-SNA/SNK-PT100 from STAUFF are designed to determine and monitor the media temperature in hydraulic reservoirs. They cover a measuring range from -40 °C to +150 °C.

They are installed either instead of the lower banjo bolt of level gauges from the SNA, SNK and SNKK series or integrated directly into the outer wall of the reservoir using a suitable adapter set.

Thanks to the platinum measuring element PT100 used (in line with EN 60751, class A), the media temperature can be recorded significantly faster, more precisely and without the usual hysteresis of up to 35 °C compared to conventional bi-metal temperature switches.

Hysteresis

Bi-metals form the basis of many conventional temperature switches. The temperature is detected by means of a bi-metal disc that switches abruptly when the switching point is reached. Normally closed and normally open contacts are available as switching functions. After cooling down to the reset point, the switch returns to its original state. The term hysteresis generally means the difference between the switching point and the reset point.

This allows immediate reaction to temperature fluctuations in the reservoir which can be communicated – e.g. to an external oil cooler – via the electrical connection of the sensor which is designed as a 4-pin round plug connector M12 with gold plated contacts (A-coded, in line with IEC 61076-2-101).

The amount of heat to be regulated in the tank is reduced and cooler performance and running time as well as the energy used are also clearly reduced. This results in less heat ageing of the hydraulic medium which may extend maintenance and replacement intervals under certain circumstances. It also has a positive effect on the durability of seals.

Typical areas of application include hydraulic applications which usually require the compensation of high temperature fluctuations to ensure proper operation of the systems and where there is a demand for optimising energy efficiency.

The simple installation process makes the TS-SNA/SNK-PT100 suitable for original equipment as well as for retrofitting during normal maintenance intervals or downtimes of your hydraulic systems.

Six Facts about Platinum Measuring Elements PT100

- PT100 are so-called RTD sensors. The abbreviation RTD comes from “Resistance Temperature Detector.” So they are temperature sensors in which the resistance depends on temperature. When temperature changes, the sensor’s resistance changes also.

- PT100 are resistors with a nominal resistance of 100 Ω at a temperature of 0 °C as defined in IEC 751 and EN 6075 respectively.

- The letters PT refer to the material from which the resistor itself is made. In this case, PT is the chemical element symbol for platinum, as defined in the periodic table of the elements.

- PT100s are robust and largely insensitive to electrical interference, making them suitable for many applications, even in the vicinity of motors, generators and other devices that carry high voltages.

- In practice, mainly PT100 are used. However, the PT500 and PT1000 versions with higher nominal resistances of 100 Ω at a temperature of 0 °C are also common.

- PT100s are usually manufactured as thin-film or wire-wound resistors. Pure platinum is usually used for production as its resistance at various temperatures is known and documented. Any change in temperature results in a known, reproducible change in resistance, so that the temperature can be derived from the resistance.

Rate and Comment

Rate posts in the STAUFF blog with just one click or leave feedback and suggestions as a comment – without registration

The editorial team of the STAUFF blog appreciates feedback and suggestions. Accordingly, readers can now not only rate all posts, but also leave comments as guests without prior registration.

And it's that simple:

- Read or view the article.

- Scroll to the bottom of the page.

- Rate the post with just one click.

- Enter a comment.

- Submit your comment as a guest (only your name is required) or create a user account.

- After the comment has been reviewed and approved by the editorial team, it will be published online.

What do you think of this new feature?

Please share your opinion with us now using the rating and comments function!

Newsletter Subscription

Receive automatic e-mail notifications about new posts on the STAUFF Blog