ACT-MLC live

Are you curious to see ACT-MLC in action? We will be showcasing our new product at two trade fairs during the week of September 2–5:

Offshore Europe 2025 Oil and Gas Asia 2025

Why corrosion protection is crucial for multiple installations

In maritime and offshore environments, corrosion is one of the biggest challenges for the operational safety of technical systems. When fastening stainless steel pipes in particular, crevice corrosion can occur in gaps between pipes and commercially available pipe clamps - for example, if salt water or moisture collects in these areas and cannot drain or dry out.

Such damaged areas often go unnoticed for a long time and lead to serious damage to the components over time. This often results in structural failure or leaks. The regular inspection of components and their replacement represents an enormous effort for the system operator and the maintenance and service providers they commission. Choosing the right pipe clamp solution is therefore a decisive factor for the longevity and safety of entire systems.

What makes ACT-MLC so special

With ACT-MLC, STAUFF is launching a new multiple pipe clamp on the market that has been specifically developed for applications in extreme environmental conditions. What makes it special: It combines space-saving multiple installation for 3 or more pipes with a proven corrosion protection concept - the STAUFF Anti-Corrosion Technology (ACT), which has already proven itself successfully with single and double clamps based on DIN 3015.

Unlike conventional multiple clamps, ACT-MLC has several integrated elastomer pads in each insert. These prevent moisture from penetrating the narrow gap between the pipe and clamp, thereby preventing one of the main causes of crevice corrosion. At the same time, the system offers the option of securely installing up to ten pipes in the smallest of spaces with just a few screws as standard - ideal for confined installation situations.

Design and functionality

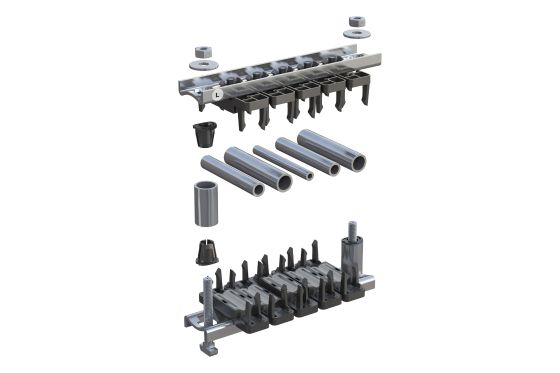

The modular design of the ACT-MLC clamp series enables flexible adaptation to different installation situations. The basic components consist of a sturdy C-profile made of stainless steel (V4A / 1.4571), high-quality inserts made of flame-retardant plastic on a polypropylene base (PP-V0) as well as matching hammerhead fastening screws and spacer sleeves.

The elastomer pads are firmly integrated into the inserts and form a permanent barrier against the ingress of water and moisture. They can be fastened in special C-rails for either three, five or ten cables - customer-specific lengths of up to two metres can also be realised without any problems.

Using the hammer-head screws, the clamps can be easily installed in many standard cable trays or mounting systems with different hole patterns.

The most important advantages at a glance:

Active protection against crevice corrosion: Elastomer pads specifically prevent moisture from penetrating between the pipe and clamp.

Compact multiple installation: Up to 10 cables can be installed in a confined space to save space.

High-quality materials: V4A stainless steel and flame-retardant plastics offer maximum resistance to corrosion, UV radiation and seawater.

Flexible mounting: Compatible with many common cable trays and mounting systems with different perforations.

Customised scalability: standard lengths and special solutions up to 2 metres available.

Perforated C-shaped metal rails made from high-grade stainless steel V4A providing structural strength and corrosion resistance

Perforated C-shaped metal rails available in standard lengths to accommodate 3 or 5 pipes or 10 pipes for maximum flexibility during assembly – custom lengths up to 2 meters can be cut to size for tailored installations.

Easy to mount into standard field trays and cable ladders with diagonal, lengthwise, and crosswise perforations using hammer head bolts and all-metal self-locking hexagon nuts

Available for the most common outside diameters for instrumentation pipework: 6,4 mm (¼ inch), 9,5 mm (⅜ inch) and 12,7 mm (½ inch) – additional diameters on request

Clamp inserts made from flame-retardant Polypropylene PP-V0 material

Integrated elastomer strips to prevent the ingress and accumulation of seawater between the clamp inserts and the pipe surface

Overall design fully compliant with Norsok Z-010 and specification S-716 of the International Oil & Gas Producers Association (IOGP) for small bore tubing and fittings, which was created as part of the Joint Industry Programme 33 (JIP 33)

Dedicated distance sleeves ensuring optimal compression on the clamp inserts and their integrated elastomer strips for peak corrosion resistance

Tested performance under real conditions

In order to prove the effectiveness of the corrosion protection, ACT-MLC was subjected to several weeks of corrosion tests with cyclical salt spray exposure. These test conditions were based on international standards and customer-specific requirements from the offshore sector.

The result: even after four weeks under extreme conditions, no crevice corrosion was recognisable on the pipelines. ACT-MLC is thus setting a new standard in the field of durable pipe fastenings for critical environments.

Assembly and choice of material

When developing ACT-MLC, great importance was attached to simple and secure installation. The screws with hammer heads and the clamp inserts with elastomer pads can be easily inserted into the perforated stainless steel C-rail and enable secure, stable and durable fastening, even under dynamic loads.

Important for maximum corrosion protection: Contact with carbon steel should be avoided during storage and installation. The use of clean tools is also recommended to protect the system from foreign particles.

The materials used fulfil high requirements in terms of fire protection, mechanical strength and chemical resistance. Operators can therefore be sure that the clamps will function reliably for many years.

Conformity to standards and areas of application

ACT-MLC fulfils the requirements of relevant standards, including

NORSOK Z-010

Specification S-716 of the International Oil & Gas Producers Association (IOGP) for small bore tubing and fittings, which was created as part of the Joint Industry Programme 33 (JIP33)

Other relevant guidelines and standards from the offshore environment

The new clamp series is particularly suitable for

Offshore platforms and Floating Production Storage and Offloading Units (FPSOs)

Shipbuilding and other maritime facilities

Industrial plants in aggressive atmospheres

Chemical plants and coastal infrastructure

Salt mines and potash mining

Thanks to its modular design, the ACT-MLC is suitable both for new installations and for retrofitting existing systems.

What is an FPSO?

An FPSO (Floating Production, Storage and Offloading Unit) is a floating offshore vessel that processes oil or gas directly from a production well, stores it temporarily and then loads it onto tankers or discharges it via pipeline. It therefore combines production, storage and export in one flexible unit - particularly suitable for remote or deep offshore fields where fixed platforms would be uneconomical.

Availability and outlook

FAQs

What does ACT-MLC mean?

What is the advantage over conventional multi-line clamps?

ACT-MLC specifically prevents crevice corrosion through elastomer coatings. At the same time, it allows several pipes to be laid in a space-saving and standard-compliant manner.

For which pipe diameters is the clamp available?

To start with: 6.4 mm, 9.5 mm and 12.7 mm. Other diameters are in preparation.

Is installation complicated?

No. The clamp fits into standard cable trays and is much easier to install than comparable clamps thanks to its modular design.

How can I obtain ACT-MLC?

Directly via one of STAUFF's worldwide subsidiaries or sales partners in your area.

Newsletter subscription

Subscribe now and don't miss any new articles!