Error reduction through colour in hydraulics

Coloured marking rings for measuring couplings and ready-made measuring hoses reduce errors during maintenance of hydraulic systems

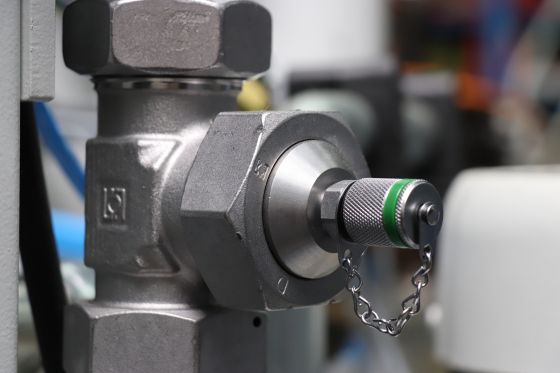

After successfully introducing solutions for marking hydraulic quick couplings last year, STAUFF is now taking the next step with the colour marking of hydraulic test equipment in the STAUFF Test series :

Hydraulic test couplings and test hose assemblies in the STAUFF Test 20 and 15 series made of steel and stainless steel have a groove in the knurled cap defined as standard. The lettering STAUFF Test is located all around this groove. In additional to that, this groove has no technical function.

From now on, operators can use this groove to further reduce the potential for errors when servicing and maintaining hydraulic systems. For this purpose, simple coloured rings are inserted into the groove. In this way, different hydraulic systems or pressure ranges can be identified within a system, different hydraulic media or coupling types can be marked or suitable positions for fluid sampling, system venting and filling can be indicated.

These rings are available in five different colours.

Flexible Retrofit Marking

This marking, which can be flexibly retrofitted in the work process, has several advantages over solutions where the protective caps or couplings are coloured in the plant: Instead of taking defined batches in different colours in advance, only colour rings have to be stocked, so that no double stock-keeping is necessary. There are only minor additional costs.

The rings are made of thermoplastic polyurethane (TPU) and can be stored for up to 10 years if properly stored. TPU has a high abrasion and wear resistance and is resistant to all media normally used in hydraulics, as well as other oils, greases and a variety of common solvents. The rings also have very good UV resistance.

The following FAQ section provides answers to the most important questions about hydraulic test couplings and test hose assemblies with colour coding.

Do you have a question? Please leave a comment below this post.

Frequently Asked Questions and Answers

FAQ section on colored marking rings for hydraulic test equipment from the STAUFF Test series

The colour coding is available for hydraulic test couplings and test hose assemblies of the STAUFF Test 20 and 15 series made of steel and stainless steel, which have a knurled cap as standard. This is the majority of all hydraulic test components manufactured by STAUFF.

Instead of the caps with knurling, variants made of plastic as well as with hexagon are also available as an alternative. For these two versions, the colour coding is currently not yet offered.

Every hydraulic test coupling and every test hose assembly of the STAUFF Test 20 and 15 series made of steel and stainless steel, which is delivered with the knurled cap defined as standard, already has a groove on this cap in which the STAUFF Test lettering is embossed all around. Rings can be inserted into this groove by the customer or user for the coloured identification of the test couplings and hoses.

The coloured rings can be used, for example, to identify different hydraulic systems or pressure ranges within a system, to mark the different hydraulic media carried in the lines, to distinguish between types of measuring couplings or to indicate suitable positions for taking samples, venting and filling the system. Ultimately, the potential for errors is reduced and assembly and maintenance are simplified.

When and where the colour marking rings are used in which colour is up to the user.

Rings for the coloured identification of the hydraulic test couplings and test hose assemblies can be positioned by the customer or user as required. No special tool is necessary for this. However, simple hook tools can facilitate the assembly. During development, particular attention was paid to user-friendliness. If necessary, the rings can be expanded by hand and moved to the appropriate position.

No, this is not currently being considered. Labelling that can be flexibly retrofitted in the work process has several advantages: instead of taking defined batches in different colours in advance, only colour rings need to be stocked so that no double stock-keeping is necessary. Only low additional costs are incurred.

Retrofitting on already installed measuring couplings and measuring hoses is of course also possible without any problems, even if the components have previously been painted, for example.

In principle, yes. However, if damage such as cracks can be seen on the rings, it is not advisable to use them again.

In that case, simply omit the colour marking rings and use the hydraulic test couplings without colour marking as before.

- Red (similar to RAL 3000)

- Black (similar to RAL 9005)

- Yellow (similar to RAL 1018)

- Blue (similar to RAL 5005)

- Green (similar to RAL 6002)

Slight colour deviations are possible due to production.

Other colours can also be supplied, depending on the required quantities.

Please contact a STAUFF sales representative for an individual offer.

The rings are subject to the same requirements as many other plastic and elastomer products.

With correct storage, the colour marking rings can be stored for up to 10 years. Correct storage means that the rings are not continuously exposed to external environmental influences.

The rings should be stored in a dry, draught-free location at constant temperatures below +25 °C and protected against ozone and strong artificial light. Failure to comply with these recommendations can cause the rings to become brittle.

No. Selecting the right material was one of the crucial criteria for the development of the colour marking rings.

Resistance to all media generally used in hydraulic systems was therefore of great importance. In addition to this, the ring material is also resistant to other oils, greases and a number of common solvents.

If you are unsure about the resistance of the rings to specific media or if you have any questions, please contact STAUFF for more information.

The thermoplastic polyurethane (TPU) used is thermally stable and also features excellent UV resistance.

Newsletter Subscription

Receive automatic e-mail notifications about new posts on the STAUFF Blog