Table of contents

- Why the right fastening is crucial

- Mistake 1: Diameters of the pipe or tube and the clamp do not match

- Error 2: Wrong clamp variant

- Error 3: Unsuitable series

- Error 4: Incorrect choice of material

- Error 5: Improper bolted connection

- Fault 6: Weak substructure

- Fault 7: Incorrect spacing and arrangement

- What to learn from typical mistakes

- FAQs

Why the right fastening is crucial

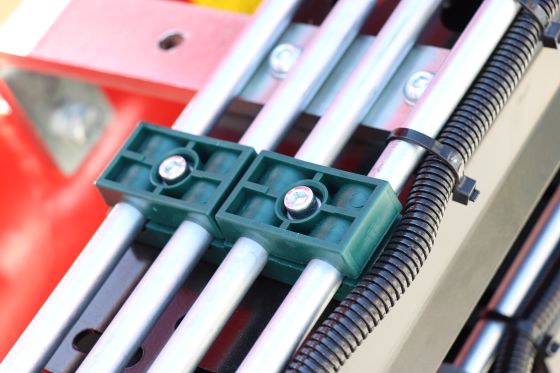

Pipe and tube clamps are more than just brackets - they are safety-relevant components in the hydraulic system. Their task is to reliably secure pipes and tubes, dampen vibrations and absorb loads. Errors in selection or installation can lead to leaks, system failures or even safety risks. This article shows the most common sources of error - and how they can be avoided.

A practical example: In a high-pressure line with an operating pressure of 420 bar, the use of an unsuitable hose clamp without pre-tensioning led to the non-standardised bolt breaking off - with production downtime and repair costs in the five-figure range. The right clamp would have prevented this.

Mistake 1: Diameters of the pipe or tube and the clamp do not match

The tube and clamp must fit together exactly. Although STAUFF clamps in accordance with DIN 3015 can compensate for smaller tolerances, the necessary preload is only created when the correct diameter is used. This is crucial for the maximum holding force in the axial direction. A small gap remains between the clamp halves and indicates this: By the way: The exact diameter is indicated on the component itself of every STAUFF clamp!

Error 2: Incorrect clamp variant

Tube clamps have a profiled inner surface - and for good reason: the ribs absorb vibrations better and provide the necessary damping. Hose clamps with a smooth inner surface are not an equivalent replacement. They offer neither the same tube holding force nor the necessary preload. If you cut corners here, you risk a loss of performance and premature failure.

Mistake 3: Unsuitable series

Whether light, standard or heavy-duty series - the differences are not just visual. With identical diameters, clamps from the heavy-duty series are significantly more robust: stronger clamp bodies, thicker cover and weld plates, larger bolt diameters. The recommended tightening torques are also higher. If you choose the wrong series, you often underestimate the load in the system.

Mistake 4: Incorrect choice of material

Every material has specific properties:

Polypropylene (PP): does not absorb moisture, but is only partially resistant to mineral oils

Polyamide (PA): good oil, UV and weather resistance

Aluminium (AL): temperature-resistant up to 300 °C, but susceptible to contact corrosion with stainless steel

The wrong material can cause the clamp to fail - for example due to softening or embrittlement. If in doubt, the recommendations in the Technical Appendix of the STAUFF catalogue or the STAUFF application specialists can help.

Mistake 5: Improper bolted connection

Pipe and tube clamps only perform to their full potential with a cover plate and hexagon head bolts as specified in the catalogue. Deviations - e.g. due to inferior or non-standardised bolts - lead to reduced holding force and can cause the bolts to break. The recommended tightening torques must be observed.

Find out more in our article on bolt strength.

Error 6: Weak substructure

Mistake 7: Incorrect spacing and arrangement

What we can learn from typical mistakes

The fastening of hydraulic pipes and tubes is not a detail - it is a safety-relevant factor. Choosing the right components and following the installation instructions not only protects the system, but also the people who work with it. STAUFF offers not only high-quality products, but also in-depth knowledge and advice.

We help you make the right choice

Find the right pipe or tube clamps now and plan a strong and durable system with our help.

FAQs

Which clamps are suitable for high-pressure pipes and tubes?

How do I recognise the correct pipe / tube diameter?

The exact diameter in mm is indicated on each STAUFF clamp body.

Can I use hose clamps as a replacement?

No, as a rule not - they do not offer the same holding force and pretension as profiled pipe and tube clamps.

What should I do if I am unsure about the choice of material?

The application specialists at STAUFF will be happy to advise you - or take a look at the Technical Appendix of the catalogue.

Newsletter subscription

Subscribe now and don't miss any new articles!