The basics

In accordance with DIN 3015, STAUFF tube clamps basically consist of a clamp body made of plastic or aluminium and additional fastening accessories made of steel or stainless steel.

This also includes cover plates, which are arranged on the top of the clamp body and fixed in place with screws. Cover plates ensure an even distribution of the forces acting on the clamp body when the screws are tightened. They are also part of the "metal cage", which ensures that cables do not fall off the system completely even if the plastic clamp fails (e.g. as a result of a fire).

A new design has already been announced for the twin series in 2024, which - as Agritechnica shows - is very popular on the market.

Introduction: What are the differences?

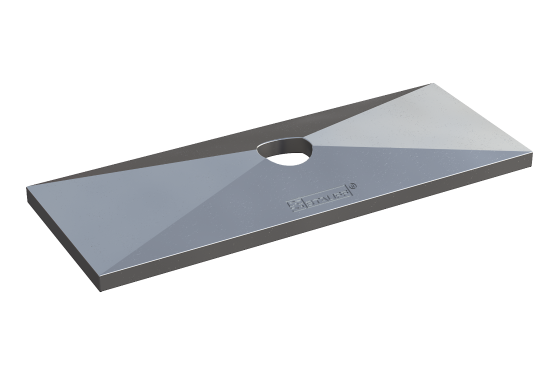

The previous cover plates tapered upwards towards the hole and had no anti-rotation device to protect the component against unintentional rotation during installation or use.

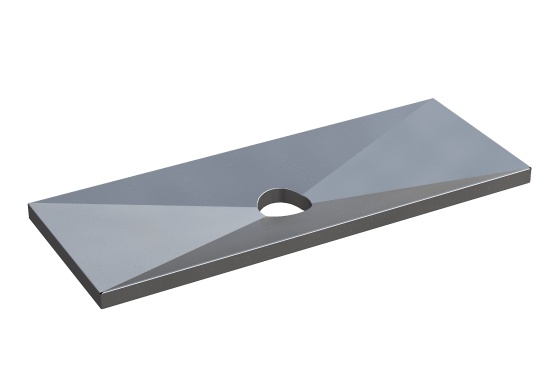

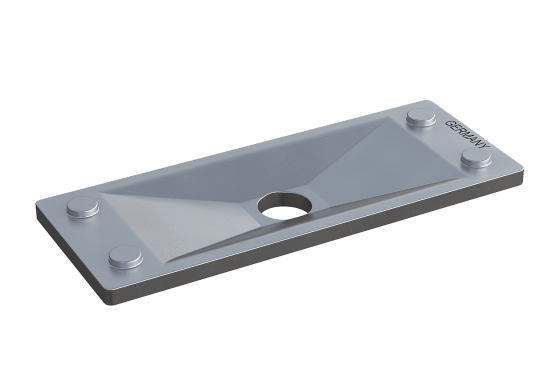

Both have now changed: the new version, which has been gradually introduced, is flattened on the top and has four studs that act as an anti-rotation device in the direction of the clamp body. This simplifies and speeds up the assembly of the components and ensures long-term stability of the assembly in the application.

These changes have no dimensional impact. The general assembly processes also remain unchanged.

Why a new cover plate?

Converting the twin series to a new cover plate was an important step in further improving the quality and functionality of our products. The new cover plate enables efficient assembly and increases the stability of the clamps. This is particularly important to ensure the longevity and reliability of our products.

The changeover: early customer involvement

Our existing customers - trading partners as well as machine and plant manufacturers - were already informed about the planned changeover at an early stage in 2024. This meant that important customer feedback - on the design of the plates themselves and also on the planned changeover process - could still be taken into account.

Visibility at the Agritechnica

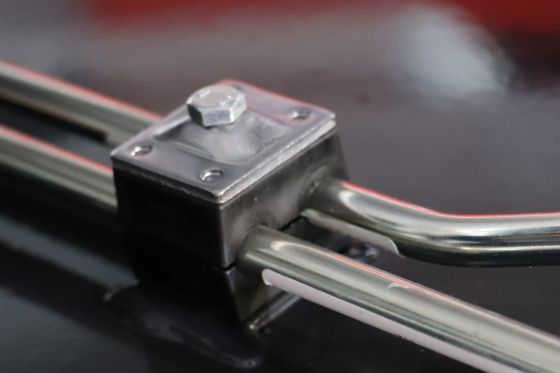

At Agritechnica, the world's leading trade fair for agricultural technology in November 2025, we were already able to see our optimised product on many agricultural machines. This clearly shows that the new cover plate has been well received and is already installed in a large number of applications. The trade fair provided an excellent opportunity to observe the spread and acceptance of our new solution in practice. The positive response and the wide range of applications at Agritechnica underline the success of the changeover and the satisfaction of our customers with the new cover plate.

Technical details of the new cover plate

Dimples to prevent twisting on the underside in the direction of the clamp body

The technical improvements of the new cover plate contribute significantly to the simplified installation and increased stability and durability of the double clamps.

FAQs

Why do you need a cover plate for clamps in the twin series?

Can clamps in the twin series also be installed without a cover plate?

In principle, this is possible, especially for pipes where no major mechanical loads due to vibrations or pressure surges are to be expected. However, the pipe retention forces specified in the catalogue are significantly reduced if the cover plate is omitted.

Is a washer required between the screw and the cover plate?

A washer is not absolutely necessary, but can be useful in the form of a lock washer to prevent the screw from loosening automatically. This contributes to the additional security and stability of the connection.

Can clamps in the twin series also be mounted on a bolt or stud?

Yes, this is possible. In this case, the bolt or stud is screwed from above with a nut. This mounting option offers additional flexibility during installation. A lock washer under the nut can also be useful here.

Newsletter subscription

Subscribe now and don't miss any new articles!