Table of contents

Technical cleanliness as a quality feature

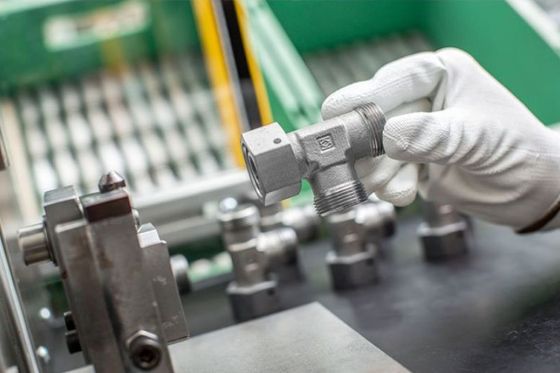

Hydraulic systems are powerful - but sensitive. Even the smallest particles can impair their function or cause damage. At STAUFF, technical cleanliness is therefore not an add-on, but an integral part of our quality philosophy. We regard it as a prerequisite for long-lasting and reliable systems - and consistently take it into account along the entire value chain.

Invisible risks before commissioning

Already during the assembly of pipe fittings and other components, particles produced during processing, transport or storage can get into the system and contaminate the medium. These contaminants are often not visible, but are technically relevant. Initial cleanliness - i.e. the condition of the components before initial commissioning - is particularly critical. STAUFF ensures that this condition fulfils the highest requirements.

Norms, standards and test methods

The ISO 16232 and VDA 19 standards define cleanliness classes based on:

maximum particle sizes

gravimetric residue weights

For hydraulic components typically apply:

Metallic particle size < 1000 µm

Gravimetry < 40 mg/cm²

These values are the basis for the design and quality assurance of modern systems.

STAUFF standards at a glance

STAUFF offers two cleanliness standards that are orientated towards market requirements:

Basic standard

Metallic particle size < 1000 µm

Gravimetry < 40 mg/cm²

Extended standard

Metallic particle size < 500 µm

Gravimetry < 20 mg/cm²

Individual packaging and sealed transport

The entire production chain - from machining and electroplating to packaging - is designed for technical cleanliness.

Measurable benefits through process control

A practical example shows the effect of our standards:

Manufacturing | Particle count | Weight / 1000 cm³ |

Conventional | 22.806 | 1.5 mg |

STAUFF | 6.253 | 0.6 mg |

The maximum particle size was also significantly reduced - at STAUFF it was 273 µm (metallic) and 213 µm (non-metallic). These values are the result of consistent process control and modern cleaning technology.

Investment in cleanliness - with a system

Compliance with the extended standard requires additional work steps:

Cleaning before and after electroplating

Transport in closed containers

Clean room assembly

Individual packaging according to the state of the art

These measures incur additional costs - around a factor of 5 compared to the standard process. But they pay off: Fewer returns, lower maintenance costs and a longer service life for the systems.

At STAUFF, technical cleanliness is part of a holistic fluid care concept - supplemented by filtration, fresh oil filtration and regular oil analyses.

Responsibility for function and service life

Whether you are a design engineer, purchaser or quality manager - anyone with responsibility for hydraulic systems should not leave component cleanliness to chance. At STAUFF, it is part of every enquiry, every quotation and every delivery. We harmonise requirements at an early stage and supply components that meet the technical and economic requirements.

FAQs

What is gravimetry?

What is initial cleanliness?

The condition of the components before initial commissioning - decisive for the function and service life of the system.

How is the particle size determined?

Using light microscopy and automatic filter analysis systems that classify and count particles.

What does the special process cost?

Depending on the article group, the cost factor can be up to 5 - depending on additional cleaning steps and packaging requirements.

Which standards apply?

ISO 16232 and VDA 19 are the relevant test standards for technical cleanliness in hydraulics.

Newsletter subscription

Subscribe now and don't miss any new articles!